What is a hot pass in welding?

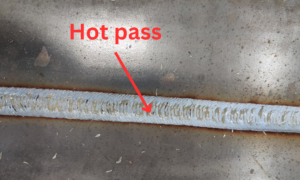

The hot pass, which is the second pass that goes over the weld root pass, helps prevent defects from appearing in the final weld and ensures that the root pass is properly fused. It adds strength to the entire joint.

To complete a hot pass, the welder must first clean the area around the root pass of any debris or other contamination that could interfere with the weld. Next, the welder must preheat the metal in the area to be welded so that it does not cool too quickly and crack.

Once the metal is preheated, hot-pass welding is performed. To ensure that the metal is properly fused, the welder must use a higher heat setting than the root pass. After the hot pass is completed, the welder must cool the area carefully to avoid cracking.

Welding basics.

Welding is the process of joining two or more materials to create a strong joint. There are many different types of welding processes, and each has its own special qualities. The secret to a good weld is to perform the process carefully and precisely. Let us start by reviewing the fundamentals of welding before getting into the intricacies of a hot pass in welding.

The Procedure of Welding

There are several processes in the welding process that all contribute to the overall quality of the weld, but the hot pass is one of the most important and requires attention to detail.

Temperature control is important.

It is crucial to maintain the proper temperature during a hot pass since temperature variations can negatively impact the weld’s metallurgical structure and weaken it. As a result, the hot pass serves as a crucial control point to guarantee the integrity of the weld.

Components of the Hot Pass.

Selecting the appropriate materials for the hot pass is crucial. Typically, materials that possess particular qualities that allow for increased temperatures are used in this stage. These materials have a major role in the success of the hot pass as well as the subsequent

Methods for Performing a Successful Hot Pass

To ensure a good finish, welders must adhere to certain techniques when performing a hot pass in welding. These techniques include managing heat input and maintaining proper travel speed, all of which require precision and skill.

Difficulties in Executing a Hot Pass

Welders encounter several difficulties when performing a hot pass, including overheating, underheating, and inadequate penetration. It is important to identify these difficulties and devise countermeasures to guarantee an error-free hot pass.

Benefits of a Welding Hot Pass

Understanding and practicing a successful hot pass can greatly improve the quality of welding projects. The benefits of a well-performed hot pass go beyond the immediate welding phase. A hot pass increases strength, stiffness, and resistance to weld defects.

Safety Procedures

Welding is a dangerous profession, and the hot pass is no exception. Wearing safety gear, having enough ventilation, and following safety procedures are crucial during this stage to keep the welder and everyone around them safe.

FAQs

What temperature is best for a hot pass?

Although this varies based on materials and welding technology, the optimum temperature for a hot pass is usually between 2500°F and 3000°F.

Is a hot pass able to cover up additional weld imperfections?

Every stage of the welding process adds to the overall quality of the weld, and although a hot pass is important, it cannot make up for basic defects in previous welding phases.

What typical errors can one avoid when making a hot pass?

A successful hot pass depends on addressing common problems such as inadequate penetration, irregular travel speed, and poor temperature regulation.

Are there any particular materials that are suggested for the hot pass?

Indeed, materials that can withstand high temperatures—like certain alloys—are frequently utilized for the hot pass in welding.

What effect does a hot pass have on the weld’s final appearance?

A well-done hot pass reduces the possibility of flaws by giving the finished weld a smoother, more consistent look.

In summary

In summary, the hot pass in welding is more than just a technicality; it is a crucial component that can make or break a weld. Every aspect of the hot pass requires precision, from material selection and technique to temperature control. As we look to the future, technological advancements will probably result in even more refinements to this crucial welding stage.

Read More: