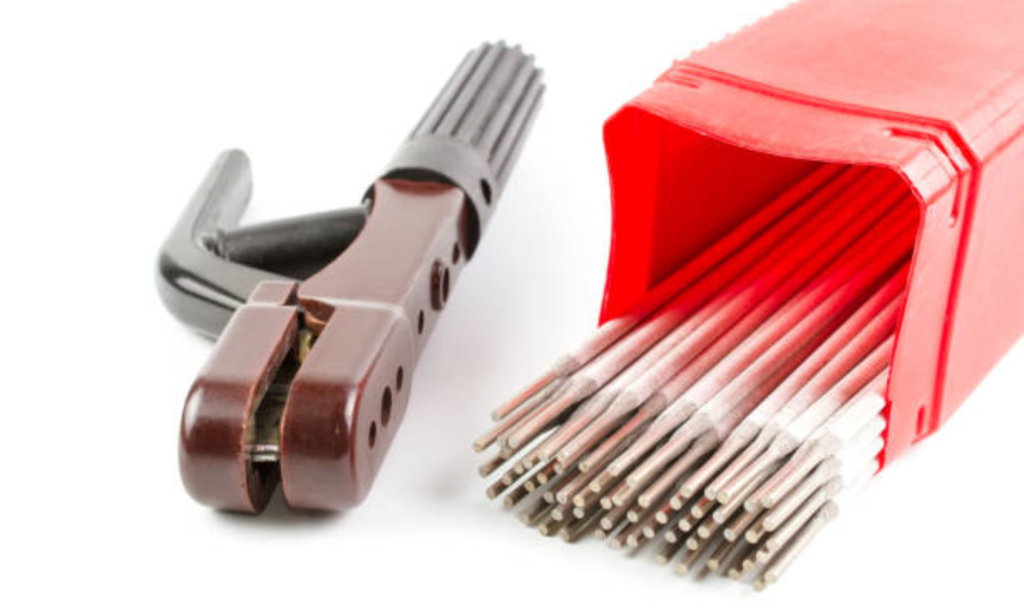

An arc welder electrode holder safely secures the welding electrode during use. The accompanying cable connects the holder to the welder to complete the circuit.

Arc welding demands precision and safety, which hinge on quality equipment from dependable electrode holders to durable cables. Essential for welders at all skill levels, an electrode holder clamps onto the electrode, providing control over the arc as well as electrical insulation to prevent shocks.

The cable, critical for conductivity, transmits current from the power source to the electrode, ensuring stable arcs for effective welding. With high-quality holders and cables, welders achieve better results, enhanced safety, and increased efficiency. These components, vital in the welding process, come in various sizes and materials suitable for different welding tasks and settings. Their design caters to the rigors of welding, ensuring lasting performance and reliability.

Introduction To Arc Welding

Fundamentals Of Arc Welding

At its core, arc welding involves an electric arc formed between a metal workpiece and an electrode. This arc generates intense heat, melting the metal and allowing it to fuse. It’s a simple yet mighty process.- Electric Arc: The heat source in arc welding.

- Melting: How metal turns to liquid.

- Fusing: when metals join together.

Key Components Of Welding Equipment

In the world of arc welding, every tool plays a crucial role. From the electrode holder that grips the electrode, to the cable that connects it to the power source. All parts must work perfectly to ensure a safe and strong weld.| Component | Function |

|---|---|

| Electrode Holder | Holds the electrode securely. |

| Cable | Connects holder to power. |

| Electrode | Conducts the electric arc. |

| Power Source | Provides electricity for the arc. |

The Role Of The Electrode Holder

Types Of Electrode Holders

Electrode holders come in different shapes and functions. Some are for heavy-duty use, while others are best for fine, detailed work. Let’s look at the common types:- American Type Holders: Known for their rugged build. They suit larger, industrial projects.

- Japanese Style Holders: Sleeker and lighter, these are for more delicate work.

- European Type Holders: They often feature ergonomic designs.

- German Type Holders: Typically known for their durability and performance.

Selection Criteria For Holders

Selecting the right electrode holder is key. Make sure it fits your specific needs. Look for these factors:| Factor | Importance |

|---|---|

| Material | The holder should be made from heat-resistant materials. |

| Grip Comfort | A comfortable grip lets you weld for longer without fatigue. |

| Current Capacity | It must handle the amount of current you plan to use. |

| Electrode Size | Make sure the holder can secure the electrode sizes you’ll use. |

Delving Into Welding Cables

Cable Specifications To Consider

Choosing the right welding cable is critical for any welding project. Here’s what you need to look out for:- Ampacity: The current-carrying capacity of the cable, measured in amperes.

- Wire gauge: Cable thickness affects ampacity – the thicker, the higher the ampacity.

- Length: Long cables can lead to power loss; choose the optimal length for your setup.

- Insulation: Look for durable materials like neoprene or EPDM rubber for insulation.

- Flexibility: A flexible cable makes your job easier – opt for finely stranded cables.

- Voltage Rating: Ensure the cable can handle the voltage used in your welding processes.

Maintenance Of Welding Cables

Long-lasting welding cables require regular maintenance. Here are some essential tips:- Regular Inspections: Check for abrasions, cuts, or any damage before each use.

- Cleanliness: Keep cables free from oil, grease, and other contaminants.

- Proper Storage: Coil cables loosely to prevent kinking and store in a dry place.

- Avoid Extreme Temperatures: High heat or severe cold can damage the insulation.

- Replace When Needed: Don’t hesitate to replace cables that show significant wear.

Credit: primeweld.com

Connecting The Dots: Holders And Cables

Ensuring Proper Connectivity

Good connections power a welder’s performance. Poor connections cause trouble. Here’s how to ensure proper connectivity:- Check the electrode holder’s clamping mechanism. It should grip the electrode firmly.

- Make sure the cable is free from damage. No cuts or nicks.

- Use cable connectors that match the holder. They should fit tightly with no wiggle room.

- Clean contact points reduce resistance. No dirt or rust.

Safety Measures During Connection

Connecting holders and cables also requires safety measures:- Always wear safety gloves and protective eyewear.

- Ensure the welding machine is off before setting up.

- Connect everything snugly, but do not over-tighten. It can damage threads or connectors.

- Regularly inspect for wear and tear. Safety comes first.

Optimizing Workflow With The Right Gear

Comfort And Efficiency In Welding Tasks

An ergonomic electrode holder keeps you comfortable during long welding sessions. A good grip reduces fatigue. The right cable length offers freedom of movement. Smooth workflow comes with comfort and efficiency.- Less strain on your hand

- Reduced fatigue for longer projects

- Flexible cable that moves with you

Advantages Of High-quality Equipment

Durable materials and construction mean a longer lifespan for your tools. High-quality gear ensures consistent welding results. It also minimizes the need for replacements. Below is a comparison between high-quality and standard equipment:| Feature | High-Quality Equipment | Standard Equipment |

|---|---|---|

| Material | Heat-resistant, tough | May degrade with heat |

| Design | User-friendly, ergonomic | Basic, can cause strain |

| Performance | Consistent, reliable | Variable, less reliable |

| Lifespan | Long, cost-effective | Shorter, more replacements |

Credit: www.amazon.com

Prolonging The Life Of Your Equipment

Maintaining your arc welder equipment is key to its longevity and performance. An electrode holder and cable are essential parts of your welding setup. Caring for them means less downtime and more productivity. Follow these tips to extend the working life of your gear.

Routine Maintenance Tips

Regular maintenance keeps welding equipment in top shape. Create a schedule and stick to it. Here’s how:

- Inspect cables for damage or wear daily.

- Clean the electrode holder regularly to prevent buildup.

- Check connections for tightness.

- Store equipment in a dry, safe place.

Bear in mind:

- Always disconnect equipment before maintenance.

- Replace worn parts immediately.

- Follow the manufacturer’s guidelines.

Troubleshooting Common Issues

Even with the best care, problems can occur. Use this guide to troubleshoot:

| Issue | Cause | Solution |

|---|---|---|

| Poor Arc Strike | Damaged cable | Inspect and replace if needed |

| Electrode Slipping | Loose holder | Tighten the holder |

| Overheating | Worn insulation | Check and re-insulate |

Always prioritize safety:

- Wear protective gear.

- Keep a fire extinguisher nearby.

- Never ignore a problem.

Regular check-ups and quick fixes ensure your welding equipment stands the test of time. Keep working confidently with your trusted tools.

Safety First: Working With Electric Components

Personal Protective Equipment

Wearing the right gear keeps workers safe. Start with a welding helmet, gloves, and apron. These shield against sparks and heat. Make safety a top priority. Select gear that meets industry standards. Ensure personal protective equipment (PPE) is in good condition before each use.- Welding Helmet: Protects eyes and face from sparks.

- Gloves: Insulate hands from electric shock.

- Leather Apron: Guards body from hot metal.

- Safety Boots: Prevents foot injuries.

- Ear Protection: Blocks loud noises from welding.

Best Practices For Electrical Safety

Understand the risk of electric shocks. Inspect cables and holders for damage. Use insulated tools when working with electricity. Keep a fire extinguisher nearby. Always work in a dry, clutter-free area to prevent accidents. Follow these practices:- Regularly check cables and electrode holders for wear.

- Replace damaged equipment immediately.

- Do not touch live electrical parts.

- Use equipment according to the manufacturer’s guidelines.

- Disconnect power when not in use.

Making The Investment: Cost Vs. Quality

Budgeting For Welding Equipment

Setting a budget for your welding gear is the first step. You want to ensure your investment won’t break the bank while still allowing for safe and effective welding. Below is a rundown of factors to weigh when allocating funds:- Price: Compare prices of various brands and models.

- Features: Determine which features are necessary.

- Materials: Look for durability in construction.

- Warranty: Check the warranty terms for added value.

Long-term Benefits Of Quality Gear

Investing in quality welding equipment is beneficial long-term. Poor quality may lead to frequent replacements. Here are advantages of choosing quality over cost:| Quality Gear Advantages |

|---|

| Better performance |

| Increased durability |

| Long-term cost savings |

| Enhanced safety |

| Warranty protection |

Advancements In Welding Technology

Innovations In Electrode Holders And Cables

Modern welder accessories have undergone significant changes. Electrode holders now boast ergonomic designs that reduce user fatigue. Enhanced insulation materials offer improved safety, resisting high temperatures and electrical shocks.- Heat-resistant grips

- Anti-slip surfaces

- Quick-release mechanisms

| Feature | Benefit |

|---|---|

| Superior Conductivity | Efficient energy use |

| Robust Insulation | Increased safety |

| Lightweight Build | Enhanced portability |

The Future Of Welding Equipment

The trajectory for welding technologies points towards more innovative solutions. Future electrode holders could feature smart sensors that monitor grip pressure and adjust automatically. Similarly, cables may incorporate self-diagnostic capabilities to alert users of wear or upcoming failures, ensuring uninterrupted operations.- Smart electrode holders

- Self-healing cable materials

- Wireless control systems

Conclusion: Equipped For Success

Recap Of Essential Gear Insights

Important points to remember are:- Electrode Holder – It must be comfortable and firm. A secure grip equals precise welds.

- Welding Cable – It should be flexible and durable. Quality cables ensure safety and efficiency.

- Compatibility – Holder and cable must match your welder’s specifications.

Final Thoughts On Equipment Selection

Final equipment choices matter. They affect your welding and safety.| Feature | Benefit |

|---|---|

| Sturdy Holder | Ensures consistent welds |

| High-Quality Cable | Provides electrical safety |

Frequently Asked Questions Of Arc Welder Electrode Holder And Cable

What Is An Arc Welder Electrode Holder?

An arc welder electrode holder is a clamping device for holding the electrode securely during the welding process. They come in various designs and are essential for maintaining a stable electric arc for effective welding.

How Do I Choose The Right Cable Size For Welding?

To choose the right cable size, consider the welder’s output amperage, cable length, and duty cycle. Cables must be thick enough to handle the current without overheating. Thicker cables may be required for higher amps or longer distances.

Can Welding Cables Be Repaired Or Spliced?

Welding cables can be repaired or spliced, but it must be done carefully to maintain conductivity and insulation integrity. Using proper connectors and heat shrink is crucial to ensure safety and performance.

What Is The Lifespan Of A Welding Cable?

The lifespan of a welding cable depends on usage intensity, maintenance, and storage conditions. Properly cared for cables can last several years, but frequent exposure to harsh environments or physical damage can shorten their lifespan significantly.

Conclusion

Selecting the right arc welder electrode holder and cable is crucial for any welding project. It ensures durability, safety, and precision in your work. Remember, a quality holder and the appropriate cable can significantly elevate your welding efficiency. Choose wisely to achieve those strong, reliable welds every time.